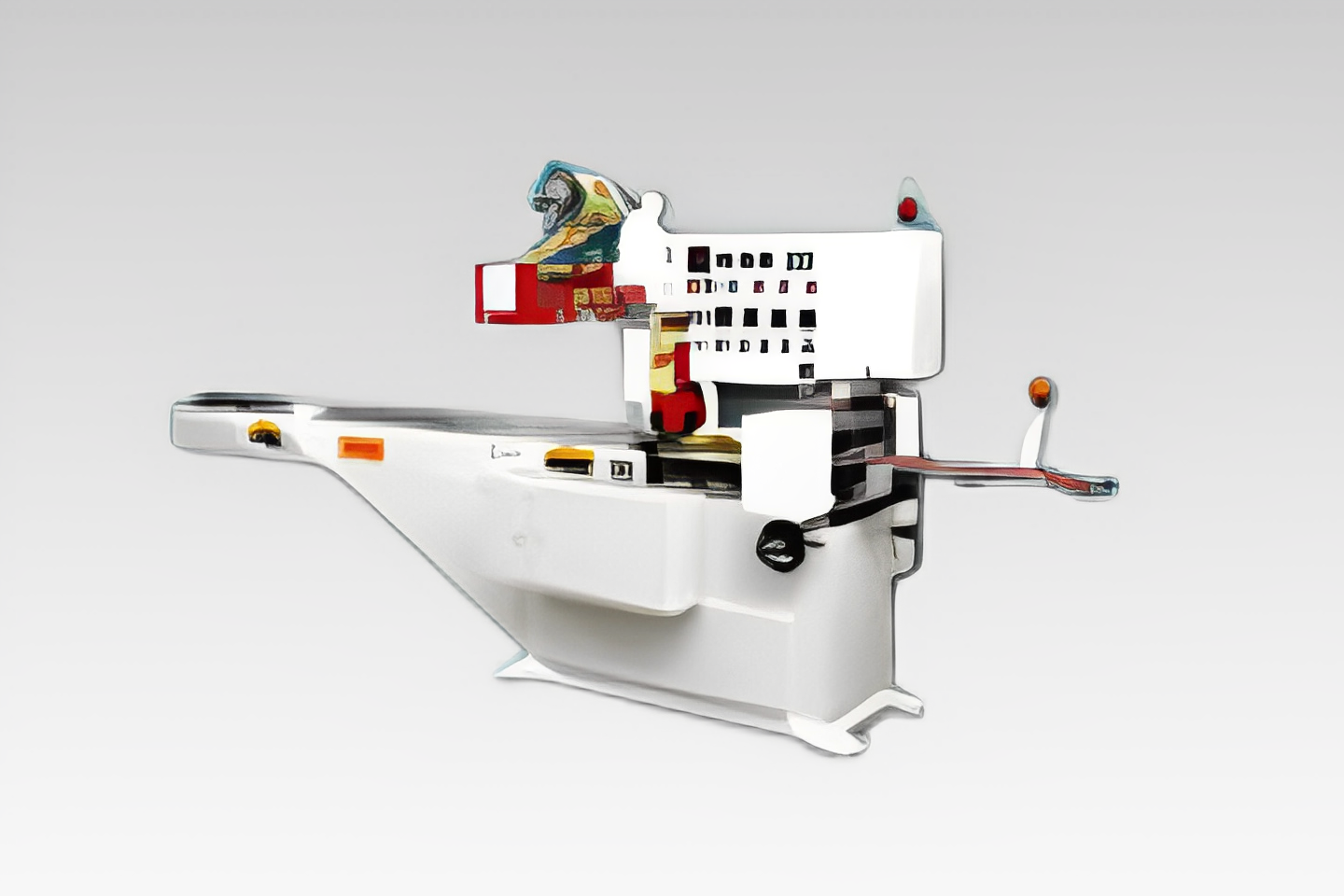

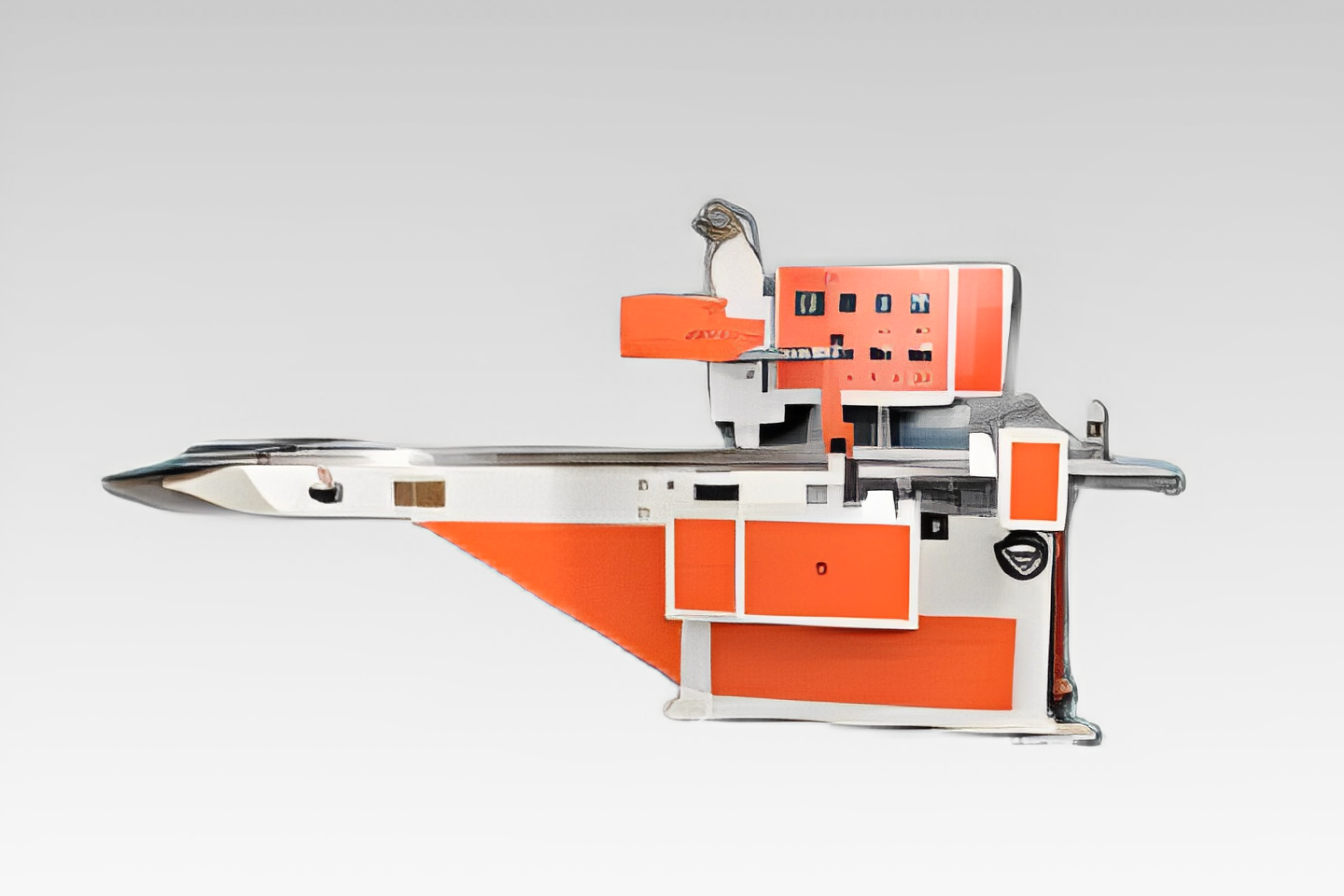

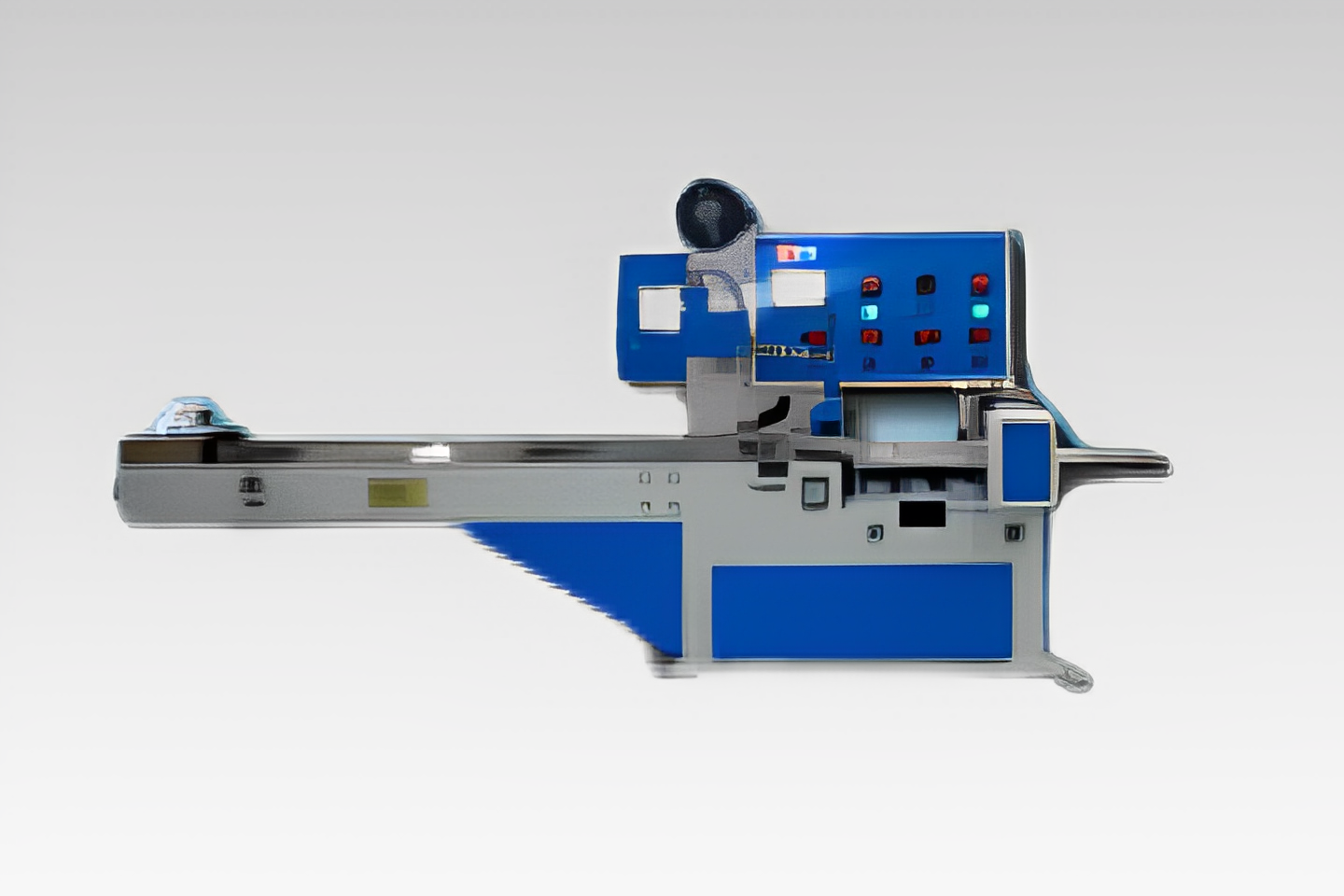

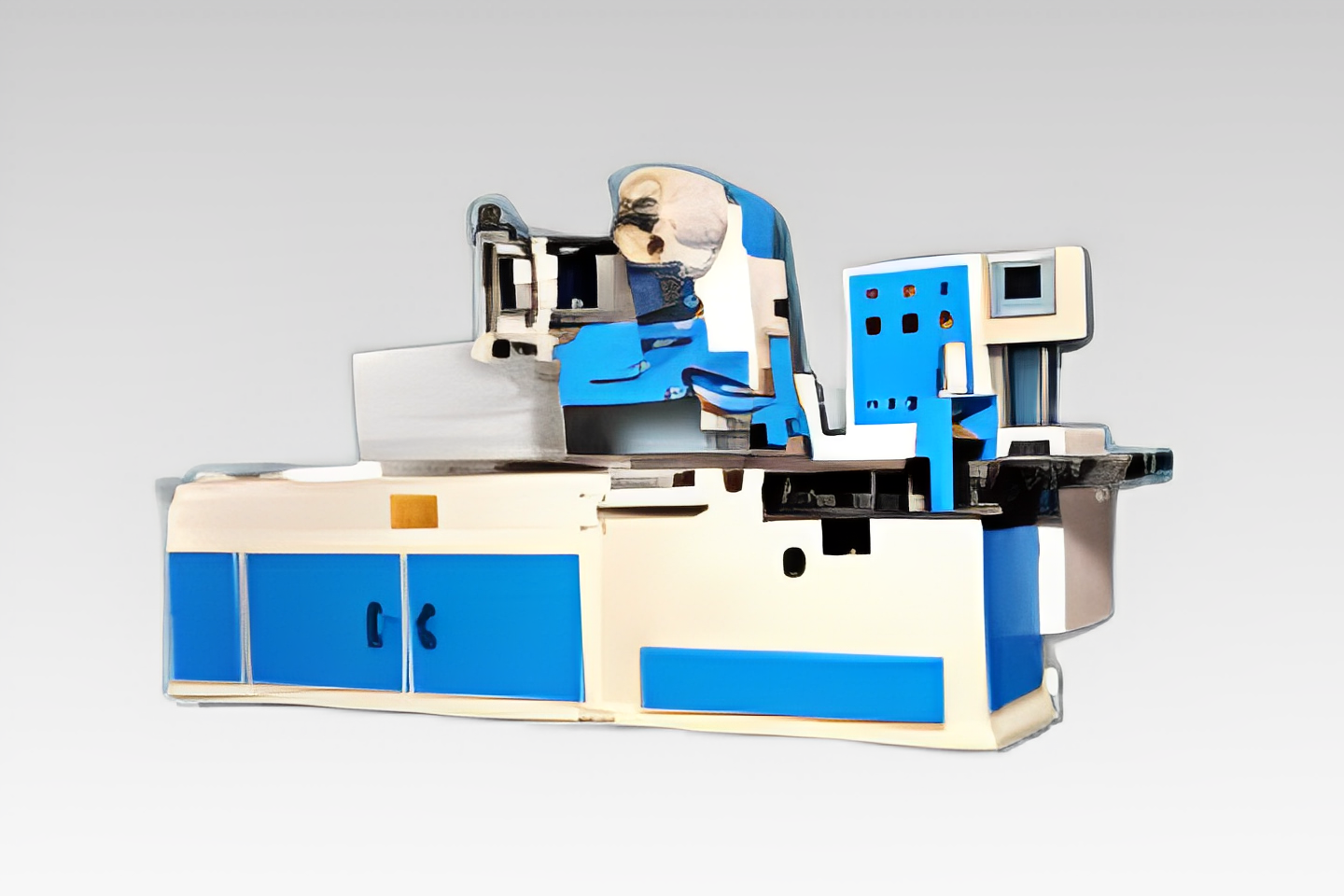

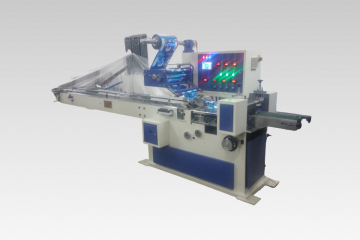

Flow Wrap Machine-016

Flow Wrap Machine-016

Horizontal Flow Wrap Machine can Pack avariety of solid products of differentshapes & sizws with all types of heatsealable films and laminators. Thesemachines are extensively used to packAppalams, Rusks, Biscuits, Bun, Chocolatebars, Ice Cream Bars, Cakes, groundnutchikkies, cotton & Bandage Roles, ScrubPads, Noodles Etc.

Key Features

-

Cantilever construction that provides for easy clinical and electrical components

-

Left to right operating direction

-

Rotary cross sealing jaws

-

Self-centering film reel holder with a operated brake system

-

Adjustable film folding box

-

For every cut length we should change timing gear wheel

-

Eye mark setting should be done for every cut length

-

If sensor misses the eve mark sensation correction should be done manually by using the forward button or else the eye mark setting should be done from the beginning

Technical Specifications

-

Operation : Electro Mechanical

-

Feeding Style : Manual

-

Packing Style : Pillow Type Centre Seal

-

Product Size : Width 30 mm to 100 mm, Length 30 mm to 150 mm Height 05 mm to 50 mm

-

Packing film size : Width 100 mm to 300 mm, Cut Length 75 mm to 200 mm

-

Production Output : Approx 20 to 80 Packs / minutes (Depending up on Product Size)

-

Packing Material : All type of laminated (BOPP, LD Polyester, Aluminum Foil)

-

Motor : 1/2 HP Three Phase 440V, 50Hz

-

Heater : 220v, 1400 watts

-

Power : 2 kw

-

Machine Dimension : Length 2850 mm, Width 1000 mm, Hight 1500 mm Approx

-

Machine Weight : 500 kg Approx